What Is Nonwoven Fabric?

Nonwoven fabric refers to materials that are not woven using traditional warp and weft methods. Instead, they are made by bonding fibers through physical, chemical, or mechanical processes to form a fabric-like sheet. The invention of nonwoven fabric revolutionized the textile industry by skipping the complex weaving stage and offering advantages such as diverse raw materials, shorter processing time, faster production speed, lower cost, and broad applications.

In everyday life, nonwoven materials are everywhere—from medical masks and sheet masks to cotton pads, gauze wipes, wet wipes, diapers, sanitary pads, shopping bags, cleaning cloths, apparel, surgical gowns, bandages, air filters, and medical hygiene materials.

🔗 Learn more: GRAMINTON ‘s nonwoven product applications

Raw Materials of Nonwoven Fabric

Nonwoven fabrics are made from fibers, which may be natural cellulose-based or synthetic polymer-based. Natural fibers include cotton, flax, jute, wool, and silk. Synthetic fibers include rayon, polyamide (PA), and polypropylene (PP). While natural fibers are less accessible and more expensive, synthetic fibers—thanks to modern technology—retain natural fiber benefits while adding enhanced functionality and lower cost.

There is no absolute winner between natural and synthetic fibers. The right material depends on the use case. Today, most nonwovens are made from blends of both, leveraging different ratios and processing methods to achieve diverse performance characteristics.

Basis Weight of Nonwoven Fabric

The unit used for nonwoven fabric is basis weight, referring to the weight per square meter, written as g/m² or gsm (grams per square meter). A higher number typically means a thicker material. Products can be made in different weights depending on the application. For example, disposable cross-roll bed sheets come in 25g, 30g, or 40g options, allowing beauty professionals to choose the desired thickness. Differences in basis weight often explain price variations even when the material type is the same.

Types, Uses, and Products Made with Nonwoven Fabrics

◎ Cotton-Based Nonwoven (Spunlace)

Spunlace nonwoven is produced via hydroentanglement, where high-pressure water jets entangle cotton fibers to form fabric.

- Features: Soft and delicate, strong and durable, highly absorbent, lint-free.

- Applications: MiaoMiao Bear’s disposable gauze series, such as cotton wipes and baby bath towels; NIKITA’s ultra-soft collection including facial towels, hair wraps, stress-relief cloths, and bath towels; Hukejie’s home care wipes; commonly used in wet wipes and mask inserts.

◎ Airlaid Nonwoven (Dry-Laid Wood Pulp)

Airlaid paper is made using a dry-laid process, where loose fibers are bonded with adhesives through impregnation, spraying, coating, or foaming.

- Features: Thick texture, high loft, excellent water absorption.

- Applications: MiaoMiao Bear’s thick care wipes (for dry and wet use); NIKITA’s ultra-soft thick towels; LICK’s multipurpose cleaning wipes. Also widely used in hygiene products and baby diapers.

◎ Meltblown Nonwoven

Meltblown nonwoven is created via polymer web-forming. Molten polymers are blown through fine nozzles with hot air to create ultra-fine fibers.

- Features: High density, low breathability, ideal for filtration, barrier, and oil absorption.

- Applications: Middle layer of GRAMINTON medical masks; LICK’s heavy-duty cleaning cloths. Though both use meltblown, the final properties differ based on process and need.

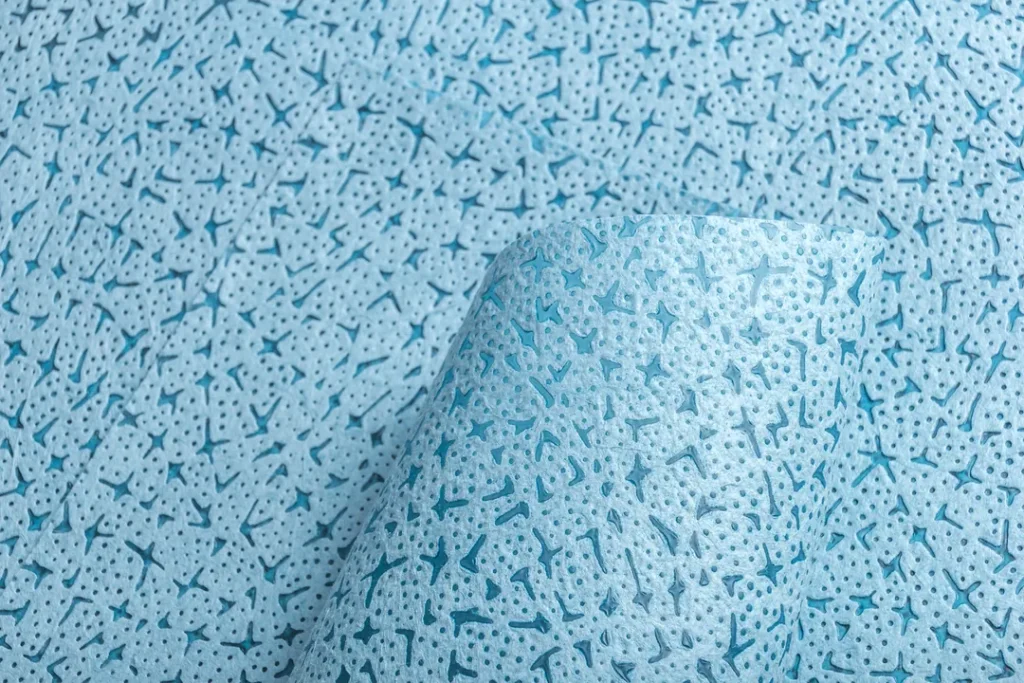

◎ Spunbond Nonwoven

Spunbond nonwoven is made by melting raw polymers, extruding them through nozzles, stretching into continuous filaments, and forming a fabric web.

- Features: Lightweight, breathable, strong, and soft.

- Applications: NIKITA’s cross-roll bed sheets, waterproof bed covers, protective liners, and foot pads. Suitable for beauty/spa use and often found in medical aesthetics, acupuncture clinics, and rehab centers.

GRAMINTON : Your Trusted Nonwoven Expert

GRAMINTON Industrial Co., Ltd. leverages its Biotech R&D Center, Nonwoven Research Center, and advanced manufacturing systems to drive innovation in nonwoven materials and develop practical products that enhance everyday convenience.

Looking for a stable, flexible, and professional nonwoven supplier? GRAMINTON offers full-scale R&D and flexible OEM/ODM services. Whether you’re a brand or distributor, we provide tailored product solutions aligned with market demand.

Ready to Start ? Contact Graminton for a Tailored Evaluation Today.

Contact Us

Welcome to contact us by filling out the form.